Welcome to our Knowledge Base

Foundational Guidance for Contractors on risk-based Temporary Traffic Management (TTM)

The Context: A New Approach to TTM

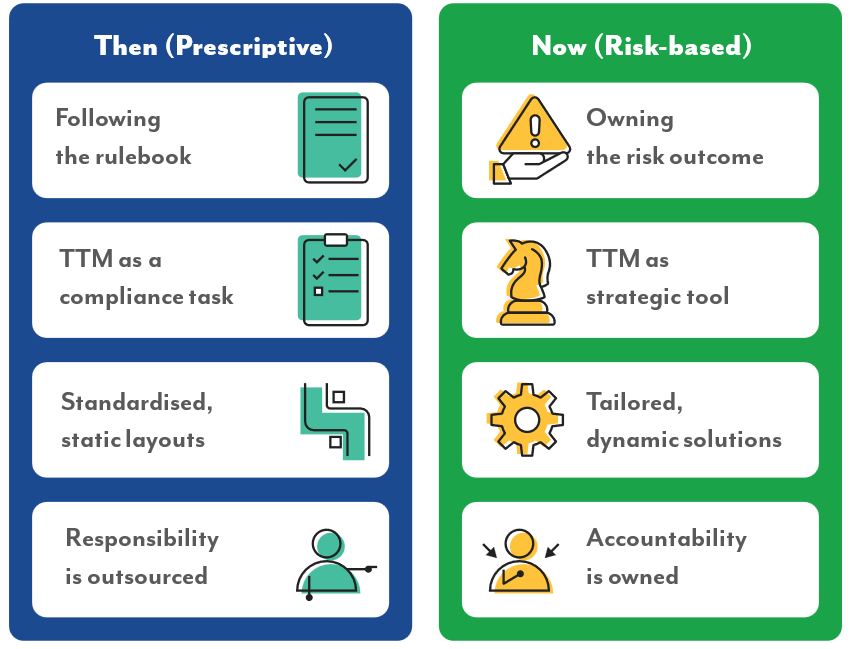

New Zealand’s approach to Temporary Traffic Management (TTM) has changed. The prescriptive Code of Practice (CoPTTM) is retired. The new environment, guided by the NZ Guide to TTM (NZGTTM), is built on risk-based principles.

This is not a simple procedural update; it is a philosophical shift. It invites contractors to move beyond compliance and take direct ownership of how they manage risk at their worksites.

Parallaxx champions this change. We believe contractors should take control of their TTM process and supply chain. This means building in-house capability and creating a contracting environment that delivers right-sized, effective TTM. Our role is to partner with you to make this happen. This guide provides a foundational roadmap.

The core message here is empowerment. We advocate for contractors to take back control of their TTM. This might mean building their own design team, or it might mean becoming a more intelligent, demanding client of an external design house. The key is that the contractor, who owns the overall project risk, must own the TTM risk strategy. Our role at Parallaxx is to be the expert partner that helps them achieve this, whichever model they choose. Your design should feel empowering and strategic, not just instructional.

Who is this guidance for?

This guidance is for the leaders and planners within civil and utility contracting organisations who are responsible for delivering work in or near the road corridor. This includes:

Civil Contractors (roading, structures, land development)

Civil Contractors (roading, structures, land development)

We need to be specific about the audience. These are the organisations physically doing the work. The “3-waters” (stormwater, drinking water, wastewater), electrical, and gas sectors are major players in road corridor work, alongside traditional civil construction firms. The visuals should reflect this diversity of work, showing that TTM is a universal issue for anyone breaking ground

Your Role in TTM – Three Models of Capability

Contractors and TTM: Choose Your Strategy

The key to success is owning your TTM workflow. This starts with deciding on the right operational model for your business. Early, integrated planning applies to all three models.

The Outsourcer

You subcontract all TTM design and delivery

Build internal knowledge.

Train your project managers to understand TTM principles and costs.

Build internal knowledge.

Train your project managers to understand TTM principles and costs.

Take control of the supply chain.

Use multiple, vetted TTM suppliers to create competitive tension.

Build internal knowledge.

Train your project managers to understand TTM principles and costs.

Don’t just treat TTM as a commodity to be bought. This is a dangerous mindset. Become “informed buyers” – you can’t just throw the problem over the fence. Get your own people (like project managers and site supervisors) clued up on how TTM works, what it should cost, and what good looks like. You need to actively manage your supply chain by using independent cost estimations to check quotes, having more than one supplier to prevent complacency, and set up your own assurance systems (audits) to check the quality of the TTM being provided. TTM is part of your service to your client, so you must oversee it with the same rigour as any other critical component of the project

The Hybrid

You subcontract all TTM design and delivery

Be deliberate

Clearly define what work your internal team will do and where their limits are.

Manage the supply chain

For outsourced work, apply the principles from ‘The Outsourcer’

Develop focused competency

Ensure your team is highly competent and proficient in their defined roles.

Integrate systems

Align your internal methods for training, TTM design, and reporting with your key suppliers.

This model is common for mid-tier contractors. You might have a TTM planner and some of your own gear for simple jobs, but you hire bigger TTM firms for complex or large-scale work. The risk here is a disjointed approach. Our advice is to be very deliberate. Decide what you are good at in-house and focus on making your team excellent and competent at that specific work. For everything else that you outsource, adopt the “informed buyer” mindset of the Outsourcer. The most crucial point is integration. You don’t want two different systems for doing things. Your internal TTM team should align with your key external suppliers on training standards, TTM methodologies, and how performance is reported. This prevents confusion and inefficiency.

The Self-Performer

You have full end-to-end TTM capability

Integrate from day one

Bring your TTM team into the tender and planning stages.

Let experts buy

Your internal TTM leaders are your most informed buyers. Let them manage the procurement of any specialised TTM equipment or services.

Empower them to innovate

Your TTM experts can identify methods to make work faster, cheaper, and safer. Give them the mandate to influence work methodology

Often it’s the bigger contractors who have end-to-end TTM capability (but not always). Your biggest challenge is internal bureaucracy. Often, the internal TTM team is treated like a downstream service provider, brought in at the last minute to “cone off” a site that has already been planned. This is a massive waste of expertise. Our message is to bring the TTM experts in right at the start—when you are bidding for the work. They can influence the construction methodology to make the TTM simpler, safer, and cheaper. Early involvement gives them a license to innovate. Furthermore, these internal TTM experts know the market better than anyone. They should be in charge of the TTM supply chain (e.g., buying new gear or hiring specialised services) because they know what good looks like and won’t be oversold. Just remember, your internal TTM team are leaning these new ways too – don’t be afraid to challenge them if they have legacy “prescriptive” thinking.

The New TTM Landscape: From Rules to Risk

The Benefits of Agency

Doing this well provides:

Competitive Advantage

Innovative, efficient TTM methods can win tenders.

Programme Acceleration

Right-sized TTM can reduce setup times, site footprint, risk, and cost.

Safer Workplaces

A focus on actual risk leads to demonstrably safer outcomes.

This shift in the approach to TTM in New Zealand is from a passive, rule-following mindset to an active, decision-making one. You now have more agency (control and influence) over your TTM. The benefits are specific and tangible. It’s about safety and about being better in business. Smart TTM can genuinely make a project run faster and provide a competitive edge in a tender by proposing a smarter, more efficient way of managing the worksite. And of course, making work in the road safe, safer, or even safest is the ultimate goal.

The Two Distinct Phases of TTM

This is where value is created. TTM design must happen alongside your work planning, not after.

Integrate Decisions

Weave decisions about site access, equipment placement, and work phasing with TTM planning.

Be Purposeful

Justify every control measure. What risk does it treat?

This is where the plan meets reality.

Competency over Qualification

A “ticket” is not enough. The crew must have the demonstrated competency to manage the specific risks of that site.

Resources Match the Task

The crew, plant, and equipment must be appropriate for the complexity and risk of the job.

TTM is not a single activity. Design is the thinking part. It’s crucial this happens early. You can’t design the work and then design the TTM. The two must be intertwined. For example, deciding where to park machinery or how a site will be accessed are fundamental decisions that dictate the TTM. These must be made together. Delivery is the doing part. The critical point here is competency. The old system was about having the right ‘ticket’ or qualification. The new world is about proving your people are competent for the specific environment and risks they face. A qualification is part of this, but it’s not the whole story.

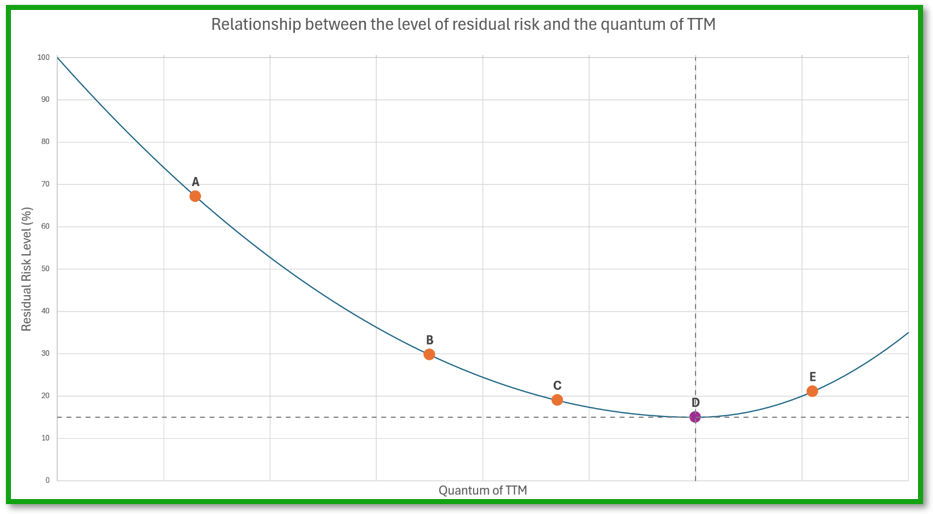

Optimisation: What is ‘Right-Sized’ TTM?

The goal is not maximum TTM or minimum TTM. It is right-sized TTM. This is the point where every control measure serves a purpose to reduce overall risk. Adding more introduces waste and can even create new hazards, while using less leaves people exposed. Good TTM planning saves more than it costs by getting you closest to this optimal point.

Use the U-shaped curve on a stylised graph (example) below

- X-axis: Amount of TTM (“Too Little” -> “Too Much”).

- Y-axis: Total Risk (“Low” -> “High”).

- Bottom of the ‘U’ is the green ‘sweet spot’ labelled “Right-Sized TTM: Lowest Total Risk”.

- Left side (red): “Unsafe for workers/public”.

- Right side (amber): “Wasteful, can introduce new hazards, erodes public trust”.

“Right-sized” is our term for the optimal amount of TTM. This is a critical concept that refutes the narrative that “less is always better.” Less can be more dangerous. However, “more” can also be dangerous and is always wasteful. There’s a sweet spot. Good planning is the tool you use to find that sweet spot and gets you the safest outcome for the most efficient cost. This is how you get “competitive advantage” by doing TTM well.

Your Path Forward & Our Partnership

A risk-based approach requires a deliberate strategy. It doesn’t happen by accident. This checklist is a tool to guide the critical conversations your leadership team needs to have. Use it to form a clear plan for developing your organisation’s TTM capability and owning your on-road workplace environments.

What to do Next: Build Your TTM Strategy

A risk-based approach requires a deliberate strategy. It doesn’t happen by accident. This checklist is a tool to guide the critical conversations your leadership team needs to h ave. Use it to form a clear plan for developing your organisation’s TTM capability and owning your on-road workplace environments.

The Question:

How will we integrate TTM design into our earliest work planning and tender processes to ensure it’s not a last-minute addition?

Why it’s important:

Treating TTM as an afterthought is the single biggest cause of inefficiency and increased risk. Integrating TTM planning early means construction methodology and safety can be designed together, leading to smarter, safer, and often cheaper outcomes.

Example:

Including a TTM strategist in the bid team for a major project. During planning, they might suggest a different site access point that dramatically simplifies the required TTM, saving time and money.

Further reading:

For more on integrated planning: TTM risk management: good supply chain management in disguise? | Civil Contractors NZ

The Question:

How will we integrate TTM design into our earliest work planning and tender processes to ensure it’s not a last-minute addition?

Why it’s important:

Treating TTM as an afterthought is the single biggest cause of inefficiency and increased risk. Integrating TTM planning early means construction methodology and safety can be designed together, leading to smarter, safer, and often cheaper outcomes.

Example:

Including a TTM strategist in the bid team for a major project. During planning, they might suggest a different site access point that dramatically simplifies the required TTM, saving time and money.

Further reading:

For more on integrated planning: TTM risk management: good supply chain management in disguise? | Civil Contractors NZ

The Question:

What specific TTM competencies do our people need, from planners to project managers, and how will we verify these skills beyond basic qualifications?

Why it’s important:

The law requires sufficient training, instruction, and supervision. A generic “ticket” doesn’t guarantee a person is competent to manage the unique risks of a specific site. Organisations must identify the actual skills needed for each role and have a system to ensure their people have them.

Example:

A company creates a competency matrix. It identifies that a Project Manager needs skills in “TTM Cost Estimation” and “Supplier Performance Review,” and provides specific in-house training and mentoring to develop these, rather than assuming an STMS qualification covers it.

Further reading:

To learn about the new approach: TTM Training is Changing – What Should I Do?

The Question:

How will we select, manage, and assure our TTM suppliers to ensure they deliver right-sized, cost-effective, and safe outcomes?

Why it’s important:

If a contractor outsources TTM, they are still responsible for the outcome. A weak supply chain means high costs, poor quality, and unacceptable risk. An intelligent, proactive approach to managing suppliers is crucial.

Example:

Before awarding a contract, a contractor requires the TTM supplier to provide evidence of their risk assessment process for a similar job. They also perform their own independent cost estimate to validate the quote.

Further reading:

For guidance on supply chain risk: Introduction to supplier relationship management | New Zealand Government Procurement

How Parallaxx Helps: Your Partner in a Risk-Based World

provide the expert services to build and execute your TTM strategy, turning risk management into a competitive advantage

Integrated TTM Planning

We help you embed TTM into your earliest work design to achieve right-sized outcomes that save time and money.

Decoupled TTM Design

We provide objective, expert TTM design that is independent of delivery, removing any conflict of interest on quantity.

Organisational TTM Systems

We partner with you to design and configure your organisation’s entire risk-based TTM strategy and operational systems.

Training & Competency Mapping

We identify the exact skills your team needs to control your TTM and build a pathway to develop that crucial internal capability.

Supply Chain Assurance

We provide independent auditing, cost estimation, and supplier evaluation to ensure your TTM partners deliver maximum value and safety.

Internal Traffic Management (VMPs)

We extend risk-based principles to your depots and yards, creating safe and efficient internal traffic flow through Vehicle Management Plans.

Assurance & Performance Monitoring

We conduct independent on-site audits and reviews to verify the effectiveness of TTM delivery and drive continuous improvement.